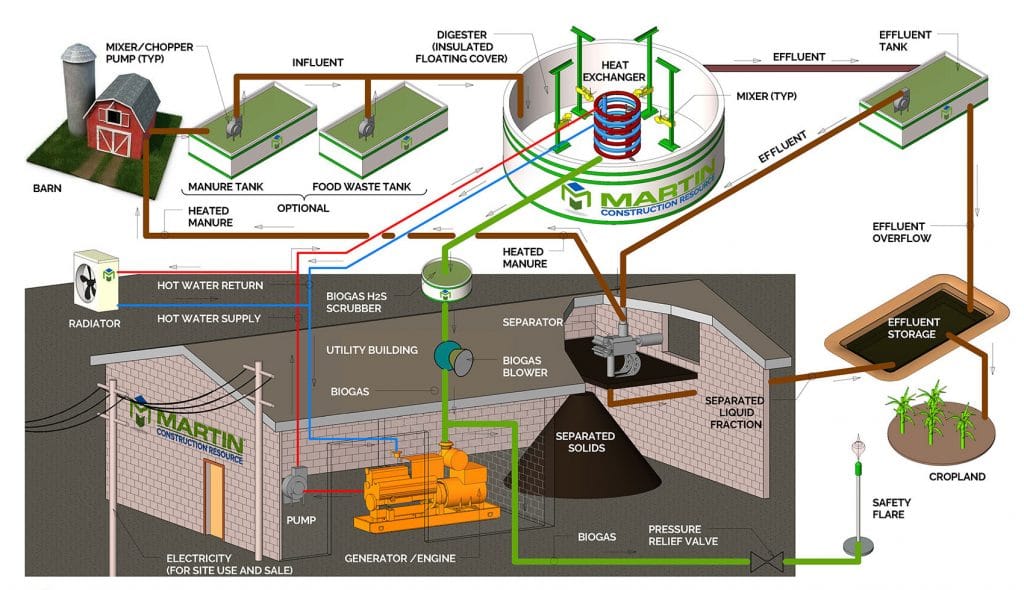

Martin Construction Resource (MCR) offers anaerobic digester solutions, including consultation, engineering, procurement, and construction. Our digesters are built with proven technology and backed by over thirty years of experience and hundreds of successful biogas projects worldwide.

Martin Construction Resource has designed and built over one hundred agricultural digesters, the first being constructed in 1982. Today, MCR routinely provides round, mixed-tank-digester and covered-lagoon-digester designs for bio-gas production from farm and/or food waste.

Custom design often results in an MCR project costing less than the competition, while meeting or exceeding the performance of other systems in bio-gas and electricity output.

Our turnkey installation services include mechanical systems, bio-gas flares, digester pumps, electrical components, piping for generator hookup, hot water systems, gas piping, electrical wiring for utility buildings, and water separator systems.

MCR’s project services also include startup, digester operations, troubleshooting, training, and warranty support.

Martin Energy Group has officially joined forces with Chomp, a manufacturer of containerized, modular anaerobic digestion systems, to continue the mission of turning waste into clean energy.

With our excellence in engineering and expertise in large-scale anaerobic digestion, we can now offer waste-to-energy solutions at any scale—serving a broad range of customers, from farms and food banks to campuses and food processors.

Together, we’re accelerating the transition to a circular economy, where waste isn’t waste at all—it’s a resource.