2019 PR-GRID

The 2019 PR-GRID was developed to introduce high-quality international investors and vendors to Puerto Rican commercial and industrial entities as part of the plan to revitalize the grid following Hurricanes Irma and Maria.

The event is hosted by New Energy Events and the Puerto Rico Manufacturers Association, have joined forces to host the 2ndPuerto Rico Grid Revitalization & Investment Forum (PR-GRID II).

The objective of the grid conference is to provide stakeholders in Puerto Rico’s power sector with insights to develop the landscape. The grid conference will provide information on how distributed generation products and services can aid the commonwealth.

The PR-GRID Objectives are as follows:

- Present a clear picture of the status of generation, transmission and distribution infrastructure following last year’s Hurricanes

- Create a marketplace for Puerto Rican municipal and industrial leaders to explore opportunities for collaboration with international investors and providers of solar, storage, LNG & microgrid products and services

- Get a complete picture of the regulatory environment and the evolving role of PREC

- Provide insight for international investors into the matrix of Puerto Rican and federal agencies and where decision-making lies

- Provide Puerto Rican authorities with qualitative insight into the spectrum of services and investors to engage in Puerto Rico

- Support institutional planning around procurement and reconstruction of Puerto Rico

Distributed & Decentralized Generation for Puerto Rico: The Investor Perspective.

Martin Energy group is a provider of generation and storage solutions for commercial and industrial customers. This panel will explore and showcase latest technologies and solutions of distributed generation. Speakers will also address the concerns around financing and deploying these technologies in Puerto Rico as well as the incentives available for developers.

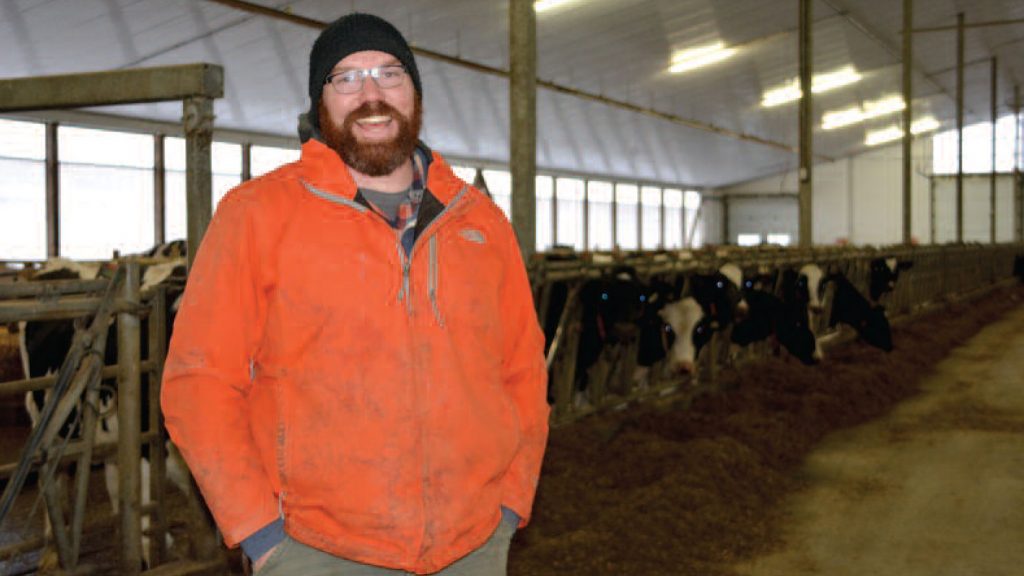

Hawkes estimates a new micro digester like McKinlay’s would cost in the area of $350,000. The biodigesters are ideal for dairy and hog farms with liquid manure. Manure needs to be in a slurry format to work in a biodigeter. The system wouldn’t work on farms that use sand for bedding. “Sand is inert and fills up the tank,” explained Hawkes. Farmers interested in installing an on-farm digester can fill an online questionnaire and will know in “about 10 minutes” if they are good candidates for the project, concluded Hawkes.

Hawkes estimates a new micro digester like McKinlay’s would cost in the area of $350,000. The biodigesters are ideal for dairy and hog farms with liquid manure. Manure needs to be in a slurry format to work in a biodigeter. The system wouldn’t work on farms that use sand for bedding. “Sand is inert and fills up the tank,” explained Hawkes. Farmers interested in installing an on-farm digester can fill an online questionnaire and will know in “about 10 minutes” if they are good candidates for the project, concluded Hawkes.