Martin Energy Group is a cogeneration engineering company that provides complete engineered power package solutions that will serve all your power needs. The design, engineering, manufacturing and performance of our Power Generation Systems are specifically built to meet your needs and specifications.

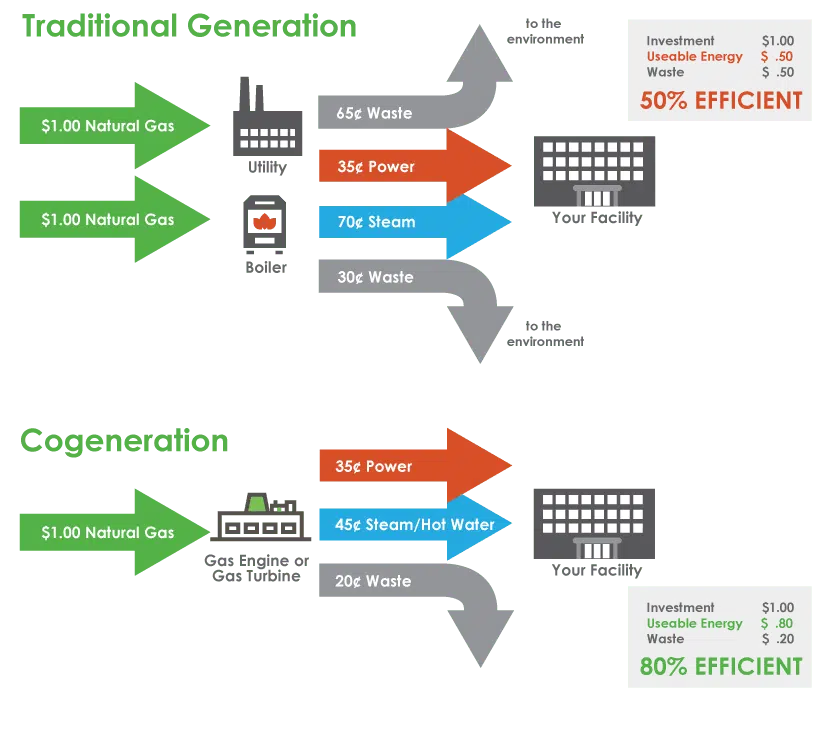

Traditionally electricity is generated at centralized power stations that are only in the region of 40% efficient. Coupled with typical 5% transmission losses, the overall efficiency is reduced to around 35%. The vast majority of the wasted energy is heat that is released into the atmosphere; while it would be prudent to use this energy efficiently, it would be both technically and commercially challenging to channel this heat to end-users due to the large distances involved.

What is cogeneration, you ask? Cogeneration (also known as Combined Heat and Power) overcomes this shortcoming by physically placing generation equipment (often an Internal Combustion Engine coupled to an alternator) within the end-user facility, creating a decentralized setup. While the mechanical efficiency of this generator is often no better than the traditional centralized setup, the thermal energy can easily be channeled into the building’s heating system, significantly reducing the fuel consumption of the on-site boiler plant.

This CHP cogeneration system setup can have an efficiency of 85% as demonstrated below, meaning that the end-user will be consuming a significantly lower quantity of energy with the resultant knock-on effect of reduced energy bills and a more environmentally friendly and sustainable building.

Want to Learn More?

CHP Systems

Combined Heat and Power (CHP) co-generation systems integrate the production of electric power and usable heat into one process. Combining these two processes means that heat is extracted while electricity is being generated. This significantly reduces waste –up to 95% of the primary energy- and makes it profitable and usable. CHP systems are installed on specific sites, thus supplying customers with heat and power directly at the point of use. This reduces the losses that occur in transmitting electric from large power plants. And utilizing thermal energy on-site increases overall efficiency. CHP systems offer a wide range of power sizes, applications, fuel types, and package options. The heat produced during the natural gas or bio-gas power generation process is recovered and can provide hot process water for heating or steam for industrial processes. Another process of hot water can be used for cooling by absorption chilling. In addition to all of these processes, the exhaust gases with proper treatment can be used for CO2 application in greenhouse systems for plant fertilization.

Power Generation System Design and Packaging

CHP systems provided by Martin Energy Group provide a cost-effective way of saving money and protecting the environment. Let us design, engineer, manufacture, and package your Power Generation System with a complete “Balance of Plant” package.

Is Cogeneration Right for You?

Why Martin Energy Group?

- Over 462 CHP Installations in 36 states/provinces

- International experience with installations in 6 countries

- Trained service & parts support staff

- Over 40 years of power generation experience

- In-house Design, Engineering, Manufacturing & Financing

- Quality equipment and value